» Product Description

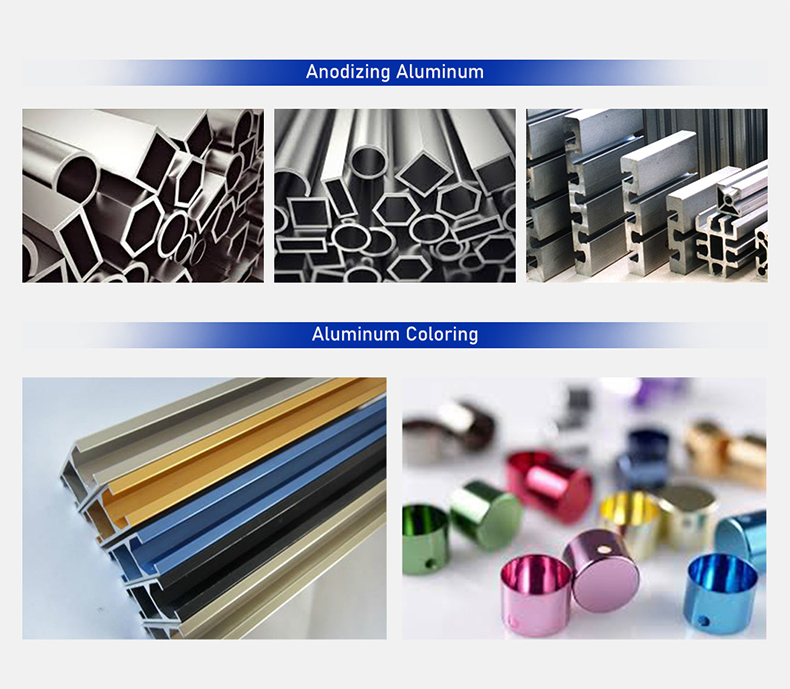

The Anodizing Rectifier delivers precise high-voltage control (up to 120V+) for hard anodizing while seamlessly supporting 25V DC/AC coloring applications, bridging both functional and decorative processes. Engineered for extreme scalability, it accommodates currents ranging from hundreds of amps to 12KA outputs, ensuring robust performance for large-scale industrial demands. Its high-frequency switching technology slashes oxide layer formation time by 30% compared to conventional rectifiers, while cutting energy consumption across operations—whether for aerospace-grade hard coatings or intricate DC/AC coloring of architectural components.

The compact, modular design guarantees ±1% voltage stability even at 25V precision levels, critical for achieving flawless color consistency in dyed finishes. This stability, combined with 12KA current capacity, enables uniform Al₂O₃ films for corrosion-resistant surfaces and repeatable results in high-stakes sectors. Post-treatments like hot-water sealing integrate effortlessly, with the DC/AC mode enhancing dye adsorption and minimizing color banding. By merging ultra-hard anodizing capabilities with 25V-12KA coloring versatility, the system reduces footprint, downtime, and operational costs—ideal for manufacturers transitioning between protective coatings and decorative finishes within a single streamlined setup.

» Product Applications

Anodizing Rectifier drives the electrochemical formation of aluminum’s oxide layer (Al₂O₃), critical for industrial applications demanding corrosion resistance and structural integrity. By delivering stable current outputs, it enables uniform growth of protective coatings with adjustable thickness (5–25μm), essential for automotive trim exposed to road salts or marine-grade architectural window frames. The technology ensures surfaces achieve 500–900 HV hardness for scratch-resistant smartphone casings while maintaining dielectric properties for heat sink insulation in 5G equipment. Post-anodizing, the rectifier-compatible sealing process locks in organic dyes for fade-resistant facade panels and medical device markings. Its adaptive voltage control (12–120V DC) supports both Type II decorative finishes on consumer electronics and Type III hard coatings for aircraft landing gear components, achieving 60% faster cycle times versus traditional rectifiers through pulsed current optimization.

1.Field application diagram:

2.Industry application examples:

» Technology Advantages

› A very thin coating

› Excellent corrosion protection

› Good electrical insulator

› Fade resistant in sunlight

› Environmentally friendly finish

› Inexpensive

› Extremely durable, hard, abrasion resistant and long lasting

» Role of Anodizing

Corrosion Resistance

Forms a protective oxide barrier against saltwater, chemicals, and atmospheric exposure, critical for marine hardware, aircraft components, and automotive underbody parts.

Surface Hardening

Achieves 300–500 HV surface hardness (vs. ~100 HV for bare aluminum), ideal for hydraulic systems, machinery guides, and industrial tooling requiring wear resistance.

Aesthetic Customization

Enables dyeing (organic/inorganic pigments) and electrolytic coloring for architectural façades, consumer electronics casings, and luxury packaging.

Electrical Insulation

Provides dielectric strength (15–25 V/μm) for heat sinks, PCB enclosures, and power distribution components needing non-conductive surfaces.

Adhesion Promotion

Microporous structure enhances bonding for powder-coated window frames, adhesive-mounted automotive trims, and composite aerospace panels.

Abrasion Resistance

Extends service life of conveyor components, firearm parts, and offshore rig equipment exposed to sand, grit, or high friction.

Thermal Management

Improves heat dissipation in LED housings, server racks, and EV battery trays via oxide layer’s emissivity (ε ≈ 0.7–0.8).

» Types of Anodizing

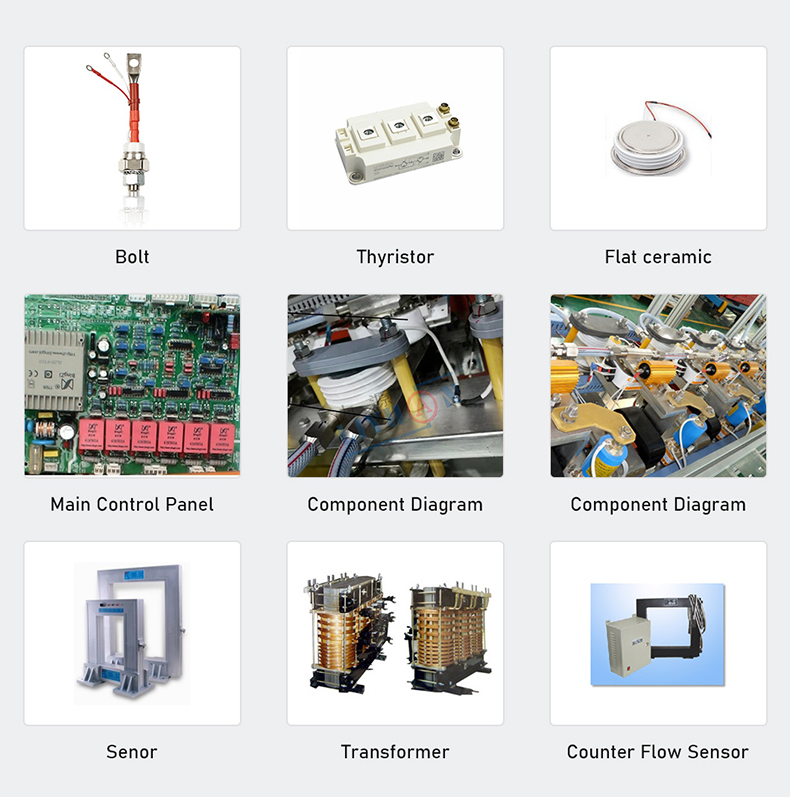

Anodizing rectifiers supply regulated current and voltage to electrochemically generate aluminum oxide layers, with core models such as the Aluminum Anodizing Rectifier (hard coating) and DC/AC Coloring Rectifier (integrated dyeing), each engineered for distinct process parameters.

› Aluminum Anodizing Rectifier

Function: Delivers direct current (DC) to form a protective oxide layer on aluminum.

Features:

Precise Voltage Control: Ensures optimal oxide film formation.

Stable Current: Prevents defects like uneven layers.

Energy Efficient: High-frequency switching technology reduces energy use.

Applications: Used in aerospace, automotive, and construction for corrosion-resistant aluminum products.

› DC/AC Coloring Rectifier

Function: Allows for both DC and AC currents to enable precise color effects in anodizing while maintaining the oxide layer’s integrity.

Features:

Dual Current Output: Enables fine control over color development.

Energy Efficiency: High-frequency switching reduces energy consumption.

These rectifiers ensure efficient, high-quality anodizing results tailored to industry needs.

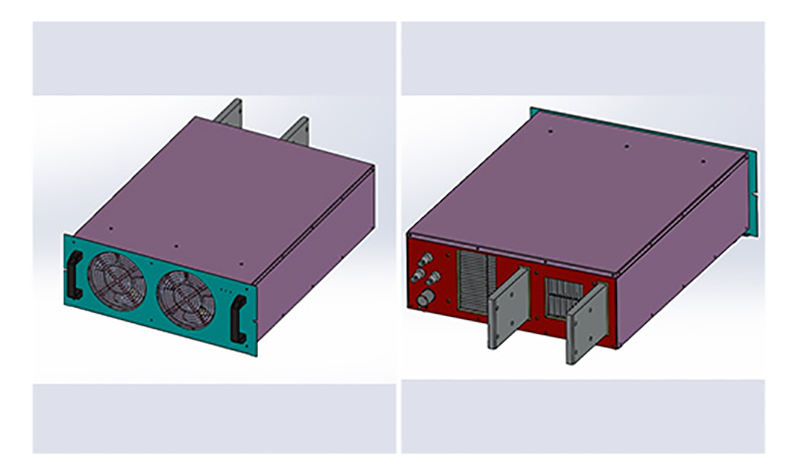

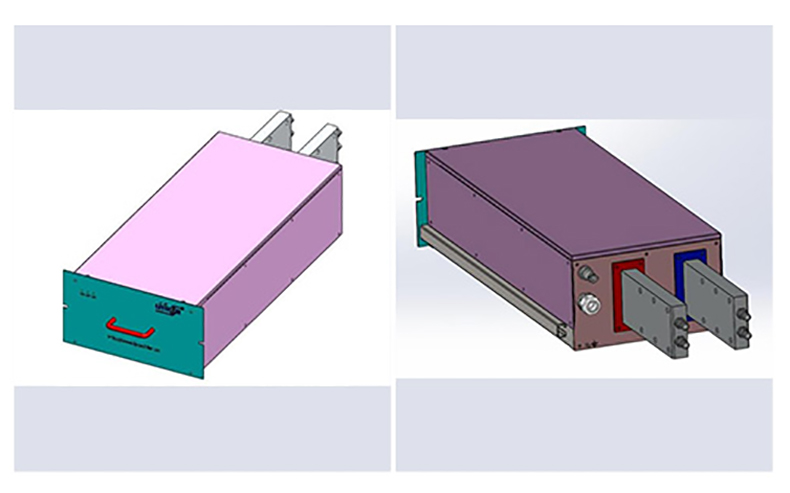

» Cooling Type for Anodizing

Air Cooling:Heat dissipation fan + air duct + comb heat sink

Water Cooling:Built-in water circulation line

» Components of silicon controlled rectifier

» Technical Parameters

| Characteristic Types | Parameter Items | Technical Requirements |

| Power Types | Power types | Silicon Controlled Rectifier |

| Model and specifications | AC/DC-20KA/30V | |

| Cooling mode | Water-cooled | |

| Switch tube type | SCR Thyristor | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC380V±10% ,50~60HZ |

| Rated Input Power | 287KW | |

| Rated Input Current | A phase, C phase AC 928A, B phase 5A | |

| Input Power Factor | COSΦ≥0.85 | |

| Output Characteristics | Output Voltage | DC:0~30V AC:0~30V |

| Output Current | DC:0~20KA AC:0~20KA | |

| According to accuracy | 1A,0.1V | |

| Rated Output efficiency | ≥85% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤1500 meters | |

| Ambient temperature | -20℃~45℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| External Dimension | Height*Width*Depth | H2300mm×W1500mm×D2300mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

» Solution

Liyuan will keep up with the world’s latest technology closely, and uphold the concept of providing customers with high-quality power supplies and professional integrated services.

With advanced design and rich experience in rectifier manufacturing, we will provide the best power solutions as well as the most stable and efficient power supply for users both at home and abroad.

» Technical Capability

LIYUAN rectifier is the most competitive brand in China

Company relies on strong technology research and development cooperation basis, created a number of advanced technology, in recent 3 years amounted to more than 30 to apply for a patent, which has nearly 10 patents of invention.

Equipped with the national electric power transformation and control engineering technology research center (branch), and has set up a loan enterprise academician workstation.

Strict implementation of ISO quality management system, and through the CE safety certification, has been implementing ERP management for many years, to achieve the network, systematic computer control, the formation of a standard, efficient modern management system.

» Qualification certification

Liyuan adhere to innovation and the continuous improvement of power conversion efficiency and product quality.

The increasing R&D investment every year, and cooperation with China’s well-known universities, we has established the research center of national electric power conversion and control engineering technology.

Especially the related core patents of high-power synchronous rectifier power supply, stay ahead of the whole industry in China.

The ISO 9001 quality management system has been fully implemented in Liyuan, including quality inspection of components in warehouse, production process inspection, and final product inspection.

We adopt advanced scientific quality management system and the most stringent testing methods in the whole process to ensure the stability and reliability of products.

» Service

› Packing

1.Small size rectifier packing in carton box separately.

2.Large size rectifier will be packed in wooden case.

3.We guarantee that all the packing is intact when it reaches its destination.

› Shipping

1.30-45 Days after payment.

2.Transport: DHL, FEDEX, UPS, Air shipping, Boat shipping

3.You may choose our shipping partner or your own partner.

› Maintenance

We are pleasant to share our theory and experience on equipment maintenance with users.

We are pleasant to interact with users to collect their tips and know-hows on equipment maintenance.

The module “Maintenance” here is intended to help users solve various problems they possibly encounter during equipment maintenance…

If you need other anodizing rectifier, we can custom design them according to customer requirements. Please contact us.

Are you looking for DC/AC coloring rectifier 30V 20KA for anodizing & metal finishing? Liyuan Haina Rectifier is one of the professional manufacturers and suppliers in this field. With over 27 years of focus on R&D, design, production, sales, and technical services for industrial rectifiers, we have already exported our products to the United States, Canada, India, Pakistan, Britain, Italy, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, and other parts of the world. Equipped with a productive factory, we warmly welcome you to purchase our high-quality, Made-in-China products at competitive prices or try our customized service.