» Product Description

In a ±15V 12500A hard chrome plating rectifier, after the AC input voltage is filtered by a rectifier circuit, high-voltage DC power is obtained. The “variable frequency conversion” stage inverts this high-voltage direct current into approximately 30kHz high-frequency alternating current. This high-frequency AC is then transformed into secondary voltage via a high-frequency transformer and filtered through a high-frequency rectifier circuit to produce the required output voltage. The electroplating rectifier employs a control circuit to sample output voltage and current. These sampled signals undergo closed-loop feedback to generate pulse width modulation (PWM) signals, which regulate the inverter circuit and maintain stable output voltage/current – a critical requirement for precision electroplating applications.

» Product Applications

Manufacturers widely use electroplating rectifier equipment for various surface treatment applications, including PCB electroplating, hard chrome coating, copper plating, nickel plating, zinc plating, gold plating, tin plating, and silver plating, among other metal finishing.

1.Field application diagram:

2.Industry application examples:

» Technology Advantages

› Modular parallel connection

› Optional N+1 redundant backup

› Capable of online hot maintenance

› RS485 digital control function

› Low-voltage MOS tube rectification

› High power factor, high efficiency

› Reasonable structural design

› Effective sealed isolation

› No water joint design inside the unit

› Practical and effective multiple protection system

› Full soft switch technology

› High reliability

› Low noise, high protection level

» Role of electroplating

Stops Rust & Chemical Damage

Zinc plating on steel parts creates a barrier against corrosion.

Reduces Wear & Tear

Hard chrome plating cuts friction, making components last longer.

Looks Matter Too

Gold finishes for jewelry / Chrome for car trim – it’s about aesthetics.

Keeps Current Flowing

We plate copper onto circuit boards because it conducts electricity best.

Better Solder Joints

Tin plating helps electronics components bond properly during assembly.

Fix Worn-Out Parts

Rebuild engine crankshafts or bearings by adding new plating material.

Specialized Solutions

Aerospace needs nickel plating: handles extreme heat.

Medical implants use biocompatible coatings so bodies don’t reject them.

» Types of electroplating

Copper Plating

Primarily for base layers – boosts corrosion resistance and helps subsequent coatings stick better.

Watch for: Oxidation (forms non-conductive patina). Always needs a topcoat.

Nickel Plating

Works as a base layer or decorative finish. Fights corrosion/wear – electroless nickel rivals chrome durability.

Heads-up: Magnetic nature messes with electronics (e.g., DIN connectors). Avoid in signal-critical areas.

Gold Plating

King of contact surfaces: Optimizes conductivity and signal clarity.

Stable performance; High cost

Palladium-Nickel Plating

Outperforms gold: Better signal transmission + extreme wear resistance.

Why it wins: Palladium’s anti-corrosion + nickel’s hardness.

Tin-Lead Plating

Was the solderability champ, now phased out (lead regulations).

Switched to: Bright/matte tin alternatives.

Silver Plating

Unbeatable conductivity/signal quality – still works when oxidized.

Downsides: Tarnishes without maintenance; premium pricing.

» Elements of Electroplating

› Cathode

The object to be plated (e.g., connector terminals or metal surfaces) where metal ions deposit into a solid coating.

› Electroplating Anodes Explained

Soluble Anodes

• Material: Matching plating metal (e.g., copper anodes for copper baths)

• Function: Dissolves to maintain metal ion concentration

• Key use: Standard plating operations

Insoluble Anodes

• Material: Non-consumable substrates (e.g., titanium/iridium oxide)

• Function: Facilitates electron transfer without dissolution

• Key use: Precious metal plating (white gold, etc.)

› Plating Solution

Contains ions of the target metal. Composition and concentration determine coating thickness, adhesion, and appearance.

› Plating Tank

Material Requirements:

• Must handle corrosive environments and thermal cycling

• Typical choices: polypropylene or titanium alloys

Role: Stores solution and maintains stable plating conditions.

› Rectifier

Converts AC to DC power to drive electrolysis.

Adjust voltage/current to control deposition speed and coating thickness.

› Auxiliary Equipment

Filters: Remove impurities from the solution.

Heaters: Maintain solution temperature.

Stirrers: Ensure uniform mixing.

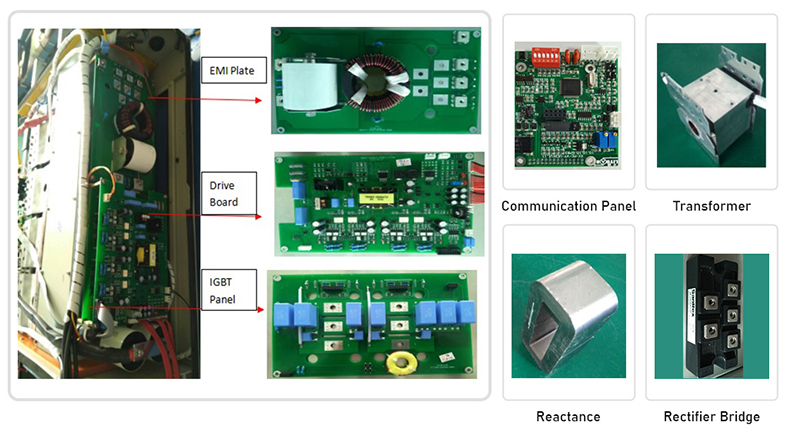

» Component Part for Electroplating

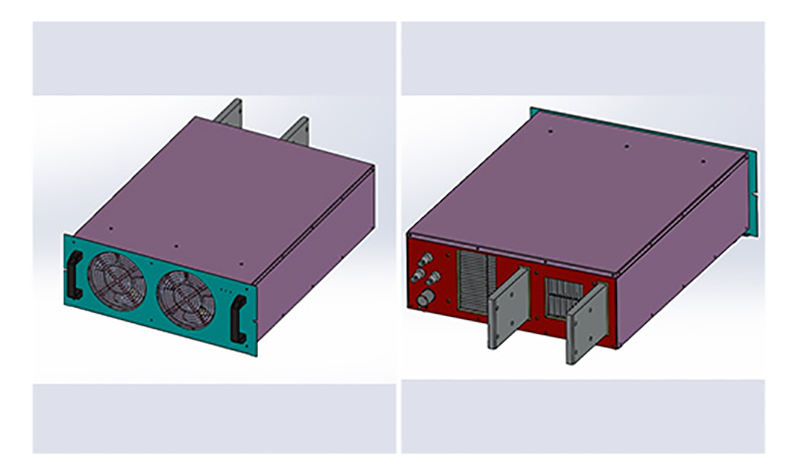

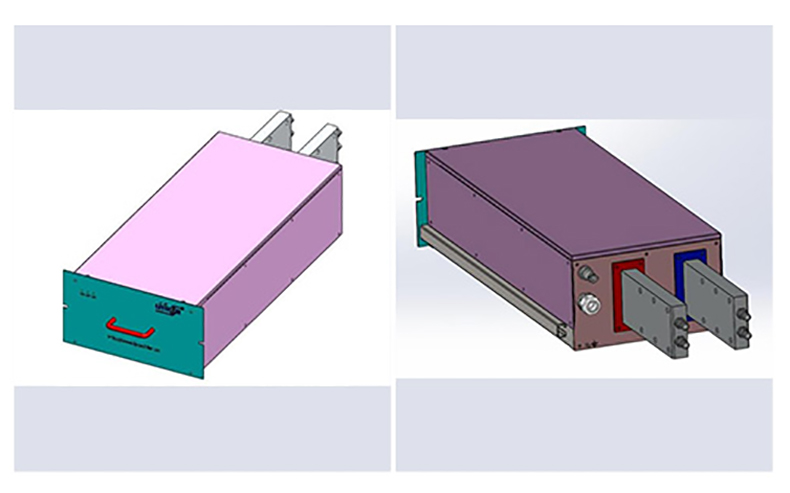

» Cooling Type for Electroplating

Air Cooling:Heat dissipation fan + air duct + comb heat sink

Water Cooling:Built-in water circulation line

» Technical Parameters

| Characteristic Types | Parameter

Items |

Technical Requirements |

| Input feature | Rate Input Voltage | Three-phase, AC380V±10% 60HZ |

| Rate Input Current | AC 330A | |

| Rate Input Power | 217KVA | |

| Input Power Factor | COSΦ≥0.95 | |

| Output feature | Output Voltage | DC 0~±15V |

| Output Current | DC 0~+12500A; 0~-12500A | |

| Stabilized Current Precision

precision Stab |

≤1% | |

| Stabilized Voltage Precision | ≤1% | |

| Ripple coefficient of the rated current | ≤3%(Rated current) | |

| Rated output efficiency | η≥91%

|

|

| Rectification feature | Constitution of the plant | The power cabinet 12500A/±15V consists of 5 TBSA-2500A / ± 15V sub-units in parallel |

| Rectifier system | full-wave rectification | |

| Insulation feature | Dielectric strength | Between primary and secondary: 2000V rms 1min; |

| Between primary and ground: 2000V rms 1min | ||

| Between control circuit and ground: 1500V rms 1min | ||

| Insulating Resistance | Input—Output:≥5MΩ | |

| Input—Chassis:≥5MΩ | ||

| Output—Chassis;≥5MΩ | ||

| Protection feature | Overvoltage, overcurrent, short circuit circuit, phase deficiency, overheating, water leakage and other protection functions | |

| Other feature | Noise | ≤60Db |

| MTBF | ≥50000h | |

| Transformer insulation grade

|

Class B | |

| Running status | The product can be run continuously at full load | |

» Solution

Liyuan will keep up with the world’s latest technology closely, and uphold the concept of providing customers with high-quality power supplies and professional integrated services.

With advanced design and rich experience in rectifier manufacturing, we will provide the best power solutions as well as the most stable and efficient power supply for users both at home and abroad.

» Technical Capability

LIYUAN rectifier is the most competitive brand in China

Company relies on strong technology research and development cooperation basis, created a number of advanced technology, in recent 3 years amounted to more than 30 to apply for a patent, which has nearly 10 patents of invention.

Equipped with the national electric power transformation and control engineering technology research center (branch), and has set up a loan enterprise academician workstation.

Strict implementation of ISO quality management system, and through the CE safety certification, has been implementing ERP management for many years, to achieve the network, systematic computer control, the formation of a standard, efficient modern management system.

» Qualification certification

Liyuan adhere to innovation and the continuous improvement of power conversion efficiency and product quality.

The increasing R&D investment every year, and cooperation with China’s well-known universities, we has established the research center of national electric power conversion and control engineering technology.

Especially the related core patents of high-power synchronous rectifier power supply, stay ahead of the whole industry in China.

The ISO 9001 quality management system has been fully implemented in Liyuan, including quality inspection of components in warehouse, production process inspection, and final product inspection.

We adopt advanced scientific quality management system and the most stringent testing methods in the whole process to ensure the stability and reliability of products.

» Service

› Packing

1.Small size rectifier packing in carton box separately.

2.Large size rectifier will be packed in wooden case.

3.We guarantee that all the packing is intact when it reaches its destination.

› Shipping

1.30-45 Days after payment.

2.Transport: DHL, FEDEX, UPS, Air shipping, Boat shipping

3.You may choose our shipping partner or your own partner.

› Maintenance

We are pleasant to share our theory and experience on equipment maintenance with users.

We are pleasant to interact with users to collect their tips and know-hows on equipment maintenance.

The module “Maintenance” here is intended to help users solve various problems they possibly encounter during equipment maintenance…

If you need other power electroplating rectifiers, we can custom design them according to customer requirements. Please contact us.

Seeking ±15V 12500A hard chrome plating rectifier? Liyuan Haina Rectifier, a professional manufacturer with 27+ years specializing in industrial rectifiers, supplies global clients including the United States, Canada, Britain, Italy, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, etc. Our advanced factory delivers cost-effective Made-in-China solutions, with competitive prices and customizable options. Contact us for sales inquiries.