» Product Description

Used extensively in manufacturing, electroplating applies micron-scale metallic coatings through controlled electrolytic reactions, improving both functional properties (e.g., abrasion resistance in engine components) and decorative finishes (e.g., jewelry gold plating).Widely used processes include copper, nickel, and hard chrome plating, with advanced systems like Polarity Reversing Electroplating Rectifiers enabling precise control for complex geometries. These rectifiers dynamically adjust current polarity, improving adhesion on ABS plastics and intricate automotive components.

The electroplating setup requires a cathode (substrate), anode (metallic or inert), electrolyte solution, and DC power supply. Modern Polarity Reversing Electroplating Rectifiers outperform traditional units by integrating bidirectional current control, achieving ±0.5% voltage stability for uniform chromium deposition. Their adaptive waveforms reduce hydrogen embrittlement in hard chrome plating while maintaining 98% energy efficiency, making them indispensable for high-volume PCB manufacturing and decorative gold/silver coatings.

In automotive applications, Polarity Reversing Electroplating Rectifiers optimize corrosion-resistant zinc-nickel alloy layers on engine parts, extending service life by 40%. The technology also supports aerospace fastener coatings, where periodic polarity reversal ensures micron-level thickness consistency. By minimizing material waste and process time, these systems exemplify innovation in sustainable surface treatment solutions.

» Product Applications

Plating rectifiers support surface treatments like PCB electroplating, hard chrome coating, and metal plating (Cu, Ni, Zn, Au, Ag).

1.Field application diagram:

2.Industry application examples:

» Technology Advantages

Electroplating Rectifier Features

› Energy Efficiency

Converts AC to DC with minimal energy loss, cutting costs for large-scale operations.

› Stable Output

Maintains stable voltage/current under load changes, ensuring even coating thickness.

› Customizable Waveforms

Adjusts pulse width, frequency, and duty cycle to match specific plating needs (e.g., pulse plating for microelectronics).

› Easy Controls

User-friendly controls (manual or automated) enable quick parameter adjustments for precision.

These features ensure reliable, high-quality plating with minimal waste.

» Role of electroplating

Enhance Wear Resistance, Conductivity & Reflectivity

Electroplating applies durable coatings (e.g., nickel or chromium) to surfaces, reducing wear from friction. This extends the lifespan of industrial tools and engine parts. For electronics, smoother conductive layers (like copper plating) improve current flow, minimizing energy loss. Silver and chromium coatings demonstrate exceptional light reflectivity (>95% at 550nm wavelength), making them indispensable in optical applications. For instance, silver-plated reflectors in laser resonator cavities achieve 99.2% reflectivity, while chromium-coated telescope mirrors maintain surface accuracy below λ/10 RMS. These metallic layers also provide critical corrosion protection through electrochemical mechanisms. Zinc-plated fasteners (5-15μm thickness) withstand 2,000-hour salt spray tests per ASTM B117, whereas automotive chrome plating (0.3-1.2μm) combines 500-cycle corrosion resistance with Ra<0.1μm surface finish.

Advanced plating techniques now integrate functional and aesthetic requirements. Medical device gold plating (99.99% purity) achieves both biocompatibility and visual appeal, while PVD-based black chrome coatings on consumer electronics provide scratch resistance (3H pencil hardness) with controlled L*30-35 blackness levels. Such processes leverage pulse reverse rectifiers to precisely control deposit crystallography, enabling <0.5μm thickness variation across complex geometries.

Dual Benefits

Electroplating isn’t just functional. It adds value:

Car parts gain sleek chrome finishes.

Circuit boards maintain stable conductivity.

Jewelry combines luxury with tarnish resistance.

Electroplating boosts both performance and visual appeal, making products last longer and look better.

» Types of electroplating

› Copper Plating

Purpose: Enhances adhesion for subsequent layers and corrosion resistance.

Note: Prone to oxidation (forms non-conductive copper oxide/green patina). Requires protective coatings.

› Nickel Plating

Purpose: Used as a base layer or decorative finish; improves corrosion/wear resistance. Electroless nickel offers chrome-like durability.

Note: Magnetic properties limit use in electronics (e.g., DIN/N connectors) to avoid signal interference.

› Gold Plating

Purpose: Optimizes conductive contact impedance and signal transmission.

Key: High stability but costly.

› Palladium-Nickel Plating

Purpose: Superior signal transmission and wear resistance vs. gold.

Advantage: Combines palladium’s corrosion resistance with nickel’s hardness.

› Tin-Lead Plating

Purpose: Improves solderability.

Trend: Phased out due to lead concerns; replaced by bright/matte tin alternatives.

› Silver Plating

Purpose: Best conductivity and signal performance.

Note: Conducts even when oxidized but tarnishes over time. Higher cost.

Selection Criteria

Match plating type to application needs: corrosion/wear resistance, conductivity, cost, and environmental regulations.

» Elements of Electroplating

› Cathode

The object to be plated (e.g., connector terminals or metal surfaces) where metal ions deposit into a solid coating.

› Anode

Soluble Anode: Made of the plating metal. Dissolves during electrolysis to replenish metal ions in the solution.

Insoluble Anode: Used for precious metals (e.g., white gold, iridium oxide). Does not dissolve but supplies electrons for reduction.

› Plating Solution

Contains ions of the target metal. Composition and concentration determine coating thickness, adhesion, and appearance.

› Plating Tank

Materials: Must resist corrosion and temperature fluctuations (e.g., polypropylene, titanium alloys).

Role: Stores solution and maintains stable plating conditions.

› Rectifier

Converts AC to DC power to drive electrolysis.

Adjust voltage/current to control deposition speed and coating thickness.

› Auxiliary Equipment

Filters: Remove impurities from the solution.

Heaters: Maintain solution temperature.

Stirrers: Ensure uniform mixing.

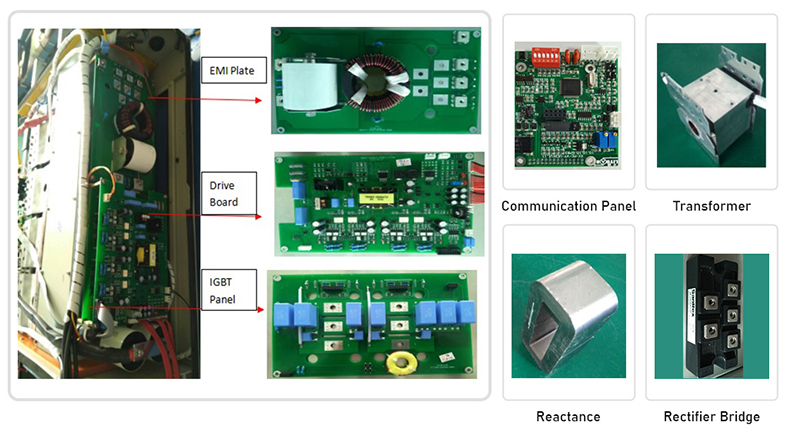

» Component Part for Electroplating

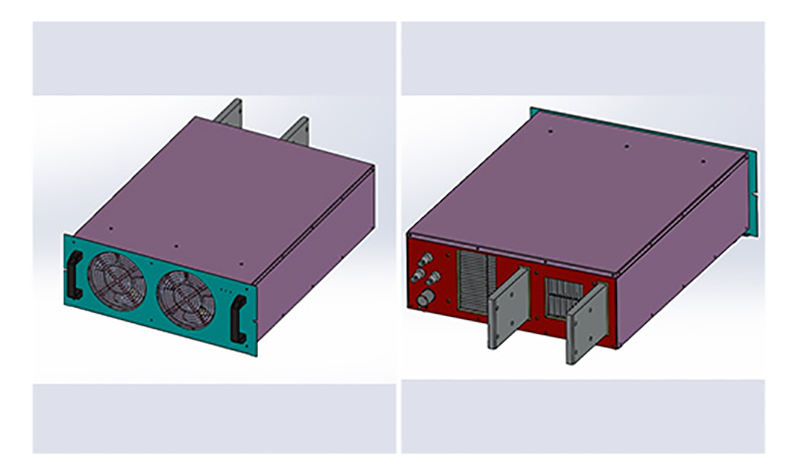

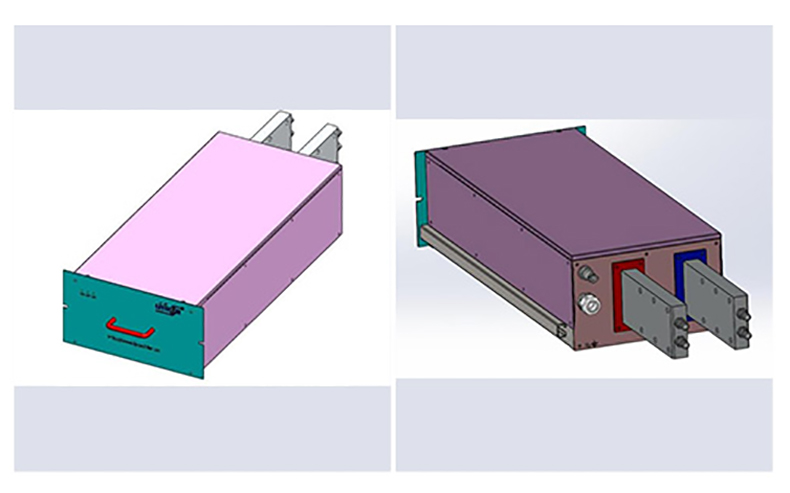

» Cooling Type for Electroplating

Air Cooling:Heat dissipation fan + air duct + comb heat sink

Water Cooling:Built-in water circulation line

» Technical Parameters

| Characteristic Types | Parameter Items | Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | HIFA-150A/±120V | |

| Cooling mode | Air-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC480V±10% ,60HZ |

| Rated Input Power | 21.1KVA | |

| Rated Input Current | AC 25.3A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC +120V/-120V |

| Output Current | DC 0~150A | |

| Stabilized Current Precision | ≤1%(Rated Current) | |

| According to accuracy | 0.1A,0.1V | |

| Rated Output efficiency | ≥90% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤2000 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| Weight | Net weight | About 100KG |

| External Dimension | Height*Width*Depth | H640mm×W480mm×D700mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

» Solution

Liyuan will keep up with the world’s latest technology closely, and uphold the concept of providing customers with high-quality power supplies and professional integrated services.

With advanced design and rich experience in rectifier manufacturing, we will provide the best power solutions as well as the most stable and efficient power supply for users both at home and abroad.

» Technical Capability

LIYUAN rectifier is the most competitive brand in China

Company relies on strong technology research and development cooperation basis, created a number of advanced technology, in recent 3 years amounted to more than 30 to apply for a patent, which has nearly 10 patents of invention.

Equipped with the national electric power transformation and control engineering technology research center (branch), and has set up a loan enterprise academician workstation.

Strict implementation of ISO quality management system, and through the CE safety certification, has been implementing ERP management for many years, to achieve the network, systematic computer control, the formation of a standard, efficient modern management system.

» Qualification certification

Liyuan adhere to innovation and the continuous improvement of power conversion efficiency and product quality.

The increasing R&D investment every year, and cooperation with China’s well-known universities, we has established the research center of national electric power conversion and control engineering technology.

Especially the related core patents of high-power synchronous rectifier power supply, stay ahead of the whole industry in China.

The ISO 9001 quality management system has been fully implemented in Liyuan, including quality inspection of components in warehouse, production process inspection, and final product inspection.

We adopt advanced scientific quality management system and the most stringent testing methods in the whole process to ensure the stability and reliability of products.

» Service

› Packing

1.Small size rectifier packing in carton box separately.

2.Large size rectifier will be packed in wooden case.

3.We guarantee that all the packing is intact when it reaches its destination.

› Shipping

1.30-45 Days after payment.

2.Transport: DHL, FEDEX, UPS, Air shipping, Boat shipping

3.You may choose our shipping partner or your own partner.

› Maintenance

We are pleasant to share our theory and experience on equipment maintenance with users.

We are pleasant to interact with users to collect their tips and know-hows on equipment maintenance.

The module “Maintenance” here is intended to help users solve various problems they possibly encounter during equipment maintenance…

If you need other power electroplating rectifiers, we can custom design them according to customer requirements. Please contact us.

Are you looking for ±120V 150A polarity reversing electroplating rectifier? Liyuan Haina Group is one of the professional manufacturers and suppliers in this field. With over 27 years of focus on R&D, design, production, sales, and technical services for industrial rectifiers, we have already exported our products to the United States, Canada, Britain, Portugal, Italy,Thailand, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, and other parts of the world. Equipped with a productive factory, we warmly welcome you to purchase our high-quality, Made-in-China products at competitive prices or try our customized service.