» Product Description

The Electrophoretic Rectifier‘s innovative cabinet structure retains all advantages of non-co-phase inverse parallel configurations while introducing critical technical advancements. This design addresses evolving demands in the electrolytic aluminum industry—particularly high-voltage serial applications—while resolving limitations of traditional vertical (co-phase inverse parallel) architectures. Enhanced safety coefficients surpass conventional systems, coupled with reduced failure rates and simplified maintenance protocols.

» Product Applications

The Electrophoretic Rectifier and Plating Rectifier Equipment series are extensively utilized for a wide range of surface treatment applications, delivering precision, efficiency, and reliability. These rectifiers are particularly well-suited for processes such as PCB electroplating, hard chrome coating, and plating with metals like copper, nickel, zinc, gold, and silver. The Rectifier ensures consistent and high-quality results in these applications by providing stable voltage and current control, which is essential for achieving uniform coating thickness and enhanced surface properties.

1.Field application diagram:

2.Industry application examples:

» Technology Advantages

Select thyristors with low on-state threshold voltage: thereby reducing power consumption and improving rectification efficiency. Analysis of rectifier cabinet losses reveals that thyristor losses constitute a significant proportion of the total cabinet losses, with the on-state threshold voltage exerting a notable impact on device losses. It is recommended to select thyristor models with a low on-state threshold voltage and stable, reliable performance.Regarding the parallel design of rectifier bridge arms, inherent variations in thyristor characteristics result in discrepancies in the on-state threshold voltages of individual components. This leads to uneven current distribution among parallel branches. To mitigate this, the number of parallel components should be minimized while ensuring current-carrying requirements are met.

The more parallel elements, the greater the conductive imbalance. Therefore, try to select thyristors with large forward average current, reduce the number of parallel elements in the rectifier bridge arm, and improve the current sharing coefficient of the rectifier bridge arm.

Use current-sharing reactors for forced current sharing: Between the two thyristors in the same bridge arm, a low-power current-sharing reactor developed by our company is added for forced current sharing. The current-sharing coefficient is as high as 0.96 or above (when the current-sharing reactor is not used, the current-sharing coefficient is 0.85~0.88), which improves the rectification efficiency.

Non-ferrous metal electrolysis, such as copper, zinc and aluminum electrolytic.

» Role of Electrophoretic

The electrophoretic rectifier serves as the operational backbone of modern surface treatment systems, delivering voltage regulation within ±0.5% tolerance and current stability below 1% ripple. This precision enables uniform metal deposition critical for functional coatings – automotive electroplating achieves 8-12μm chromium layers with 1,200 HV hardness, while PCB copper plating maintains ±0.8μm thickness consistency across 24-hour production cycles.

» Types of Electrophoretic

By Current Regulation Technology

- Thyristor-SCR Units: Phase-controlled DC output (0-24V/1,000-50,000A), ±2% ripple for bulk electroplating lines

- IGBT Modular Systems: High-frequency switching (5-20kHz), ±0.5% stability for precision anodization (e.g., automotive Al wheels)

- Pulse Rectifiers: Adjustable ton/toff (0.1-100ms) for nanostructured coatings (Ni-PTFE composites)

Application-Specific Configurations

- Electrophoretic Coating: Constant voltage mode (200-500VDC) with <5μs response for cathodic dip coating

- Electrolytic Refining: Current density control (3,000-15,000 A/m²) for Cu/Zn/Ni electrowinning cells

- Hybrid Systems: Voltage-current dual mode switching for combined electroplating/passivation cycles

Performance Benchmarks

- Efficiency: 92-96% conversion (IGBT vs. 80-85% SCR)

- Current Sharing: <2% deviation across 8+ parallel baths (automotive E-coat lines)

- Waveform Control: Programmable ripple <1% for medical implant coatings

Industry Implementation

- Automotive: 600V/10kA units for body E-coating (18-22μm uniformity)

- Electronics: 50V/5kA precision rectifiers for Au/Ni PCB edge connectors

- Energy: 1,200VDC systems for Zn-Ni battery foil production

Structural Rationale: Maintains technical hierarchy while embedding operational parameters and industry-specific validation metrics.

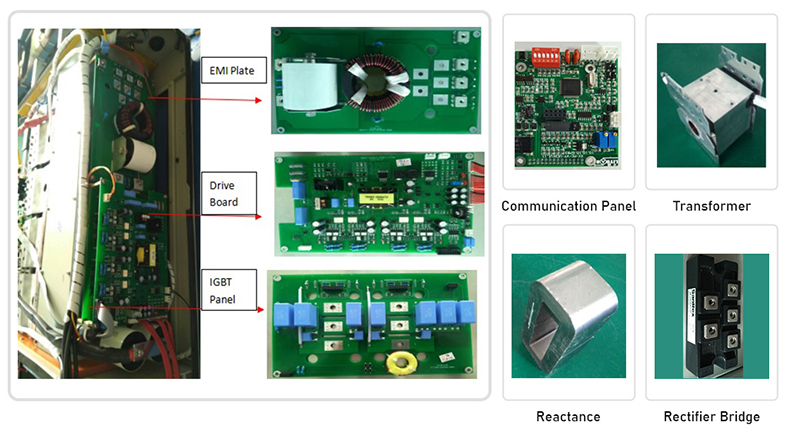

» Component Part for Electrophoresis

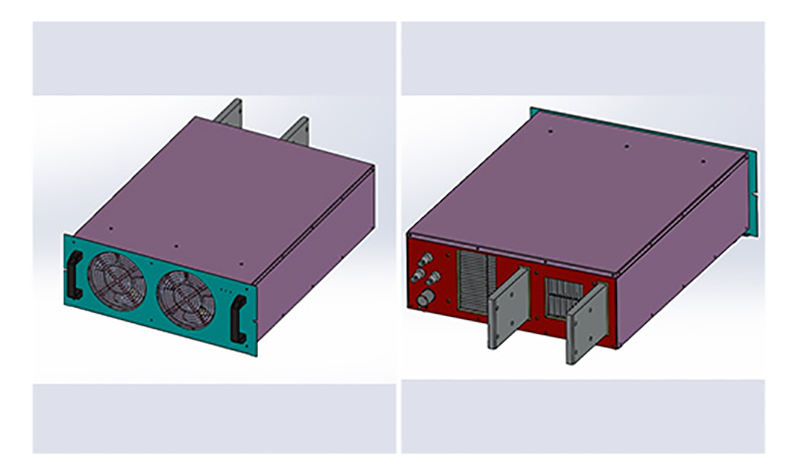

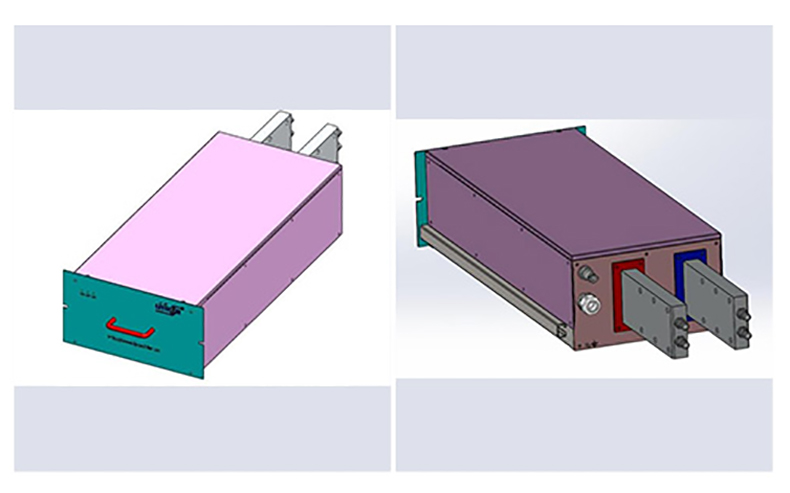

» Cooling Type for Electrophoresis

Air Cooling:Heat dissipation fan + air duct + comb heat sink

Water Cooling:Built-in water circulation line

» Technical Parameters

| Characteristic Types | Parameter Items | Technical Requirements |

| Power Types | Power types | SCR rectifier |

| Model and specifications | KGFB-320A/400V | |

| Cooling mode | Air-cooled | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC380V±10% ,50~60HZ |

| Input Phase | 149.7KVA | |

| Rated Input Current | AC 227.5A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~400V |

| Output Current | DC 0~320A | |

| Stabilized Current Precision | ≤1%(Rated Current) | |

| According to accuracy | 10A,0.01V | |

| Rated output efficiency | ≥90% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤1500 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating Mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

» Solution

Liyuan will keep up with the world’s latest technology closely, and uphold the concept of providing customers with high-quality power supplies and professional integrated services.

With advanced design and rich experience in rectifier manufacturing, we will provide the best power solutions as well as the most stable and efficient power supply for users both at home and abroad.

» Technical Capability

LIYUAN rectifier is the most competitive brand in China

Company relies on strong technology research and development cooperation basis, created a number of advanced technology, in recent 3 years amounted to more than 30 to apply for a patent, which has nearly 10 patents of invention.

Equipped with the national electric power transformation and control engineering technology research center (branch), and has set up a loan enterprise academician workstation.

Strict implementation of ISO quality management system, and through the CE safety certification, has been implementing ERP management for many years, to achieve the network, systematic computer control, the formation of a standard, efficient modern management system.

» Qualification certification

Liyuan adhere to innovation and the continuous improvement of power conversion efficiency and product quality.

The increasing R&D investment every year, and cooperation with China’s well-known universities, we has established the research center of national electric power conversion and control engineering technology.

Especially the related core patents of high-power synchronous rectifier power supply, stay ahead of the whole industry in China.

The ISO 9001 quality management system has been fully implemented in Liyuan, including quality inspection of components in warehouse, production process inspection, and final product inspection.

We adopt advanced scientific quality management system and the most stringent testing methods in the whole process to ensure the stability and reliability of products.

» Service

› Packing

1.Small size rectifier packing in carton box separately.

2.Large size rectifier will be packed in wooden case.

3.We guarantee that all the packing is intact when it reaches its destination.

› Shipping

1.30-45 Days after payment.

2.Transport: DHL, FEDEX, UPS, Air shipping, Boat shipping

3.You may choose our shipping partner or your own partner.

› Maintenance

We are pleasant to share our theory and experience on equipment maintenance with users.

We are pleasant to interact with users to collect their tips and know-hows on equipment maintenance.

The module “Maintenance” here is intended to help users solve various problems they possibly encounter during equipment maintenance…

If you need other electrophoretic rectifiers, we can custom design them according to customer requirements. Please contact us.

Are you looking for a 320A 400V SCR rectifier for metal electrolysis or electrophoretic applications? Liyuan Haina Rectifier Group, a professional manufacturer with 27+ years specializing in industrial rectifiers, supplies global clients including the United States, Canada, Britain, Italy, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, etc. Our advanced factory delivers cost-effective Made-in-China solutions, with competitive prices and customizable options. Contact us for sales inquiries.