Anodizing gives aluminum a tougher, more corrosion-resistant surface using an electrochemical method.

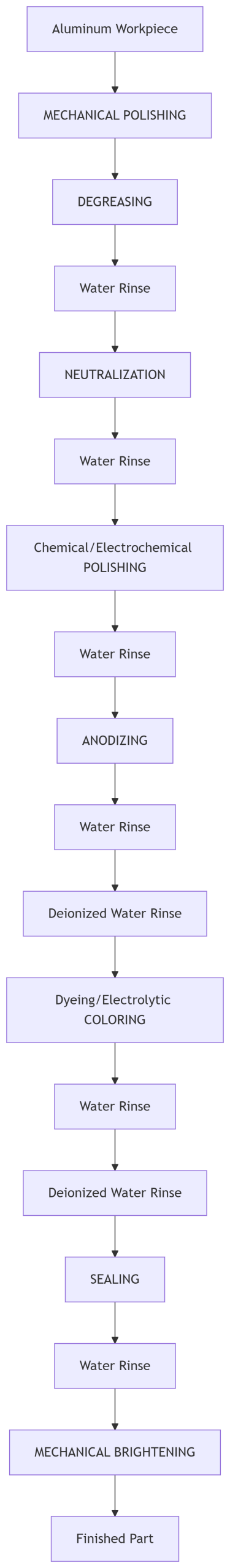

Anodizing Process:

Aluminum workpiece → Mechanical polishing → Degreasing → Water rinse → Neutralization → Water rinse → Chemical or electrochemical polishing → Water rinse → Anodizing → Water rinse → Deionized water rinse → Dyeing or electrolytic coloring → Water rinse → Deionized water rinse → Sealing → Water rinse → Mechanical brightening

Degreasing

Removes oil from the aluminum surface. A clean surface is needed for proper etching.

Alkaline Etching

Removes the natural oxide layer and any surface dirt. Also helps remove extrusion marks and adjusts the surface finish.

Neutralization

Washes off remaining alkali and neutralizes the surface. Prevents further reaction and leaves the surface clean.

Electrolytic Polishing

Uses current to dissolve rough spots on the surface. The result is a flat, bright finish.

Dyeing

The part is placed in a dye bath. Color enters the pores of the oxide layer.

Sealing

The part is boiled in water or near-boiling water. This closes the pores and fixes the color.